UV-C Light Ultraviolet Sampling System

In Accordance with: 15714:2019

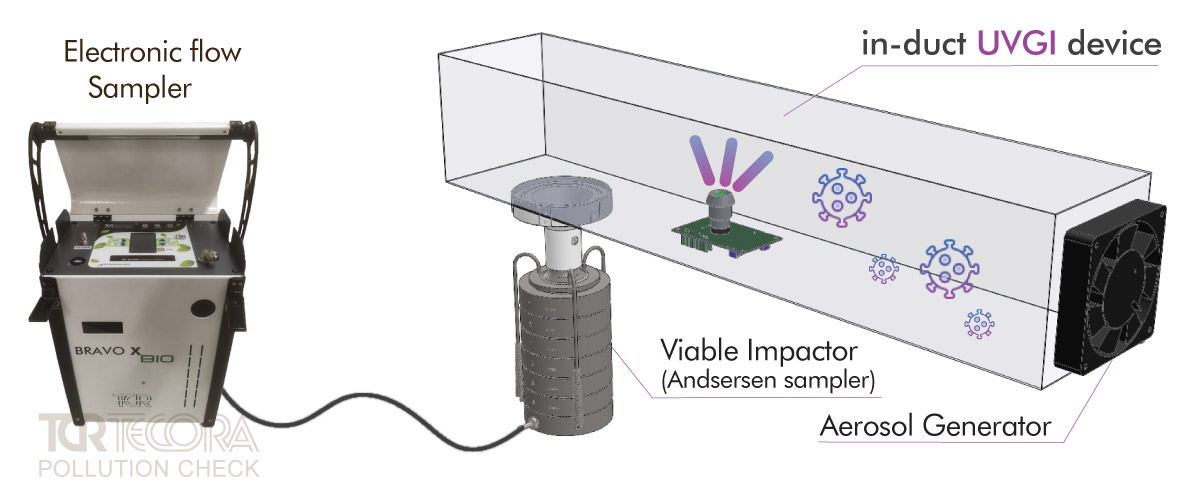

UV-C Light Ultraviolet Sampling System as well known as UV-C BioKit, is a sampling system to monitoring the Bioaerosol (Virus, Bacteria, Fungi, Spores, Protozoa Pollen, Algae) in a UVGI in-duct device using a UV-C Light Ultraviolet Lamp Irradiation Chamber, 6 Stage Andersen Impactor, Particle Nebulyzer and also an Electronic Flow Control Sampler.

How the UV-C Light Ultraviolet Sampling System works:

The UV doses is the product of UV-C irradiance and specific exposure time on a given microorganism or surface.

The longer a microbe is exposed to UV light, the higher the UV doses it will receive. In a UVGI air disinfection device, the UV doses to every single microbe is different.

Therefore, the average UV doses can be determined by the INACTIVATION RATE and a known microbial susceptibility.

Inactivation rate is expressed as N0/N (%) or log (N0/N), where N is the active microorganism concentration, and N0 the original active microorganism concentration.

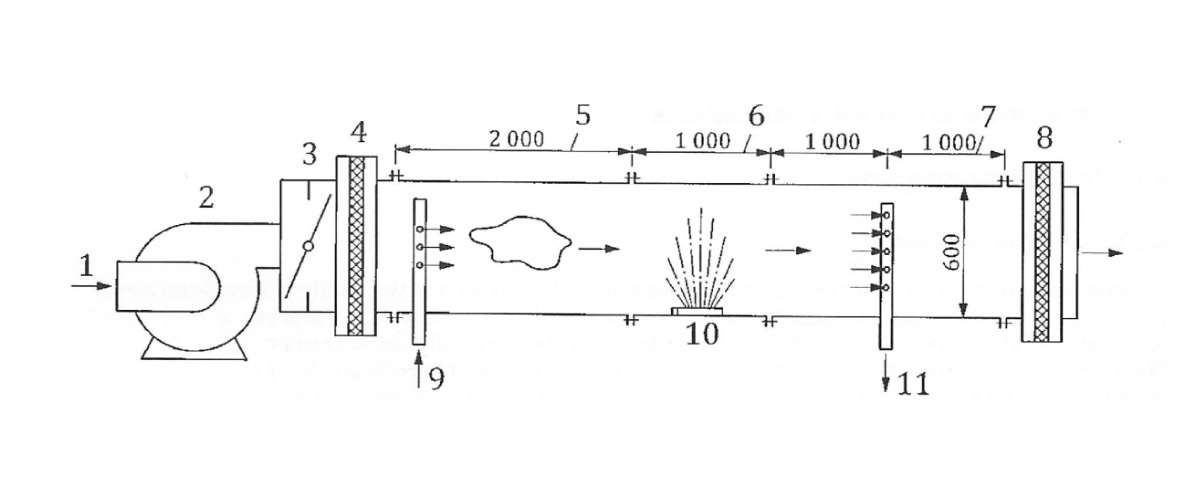

Irradiation chamber includes a blower, a damper, a HEPA filter before the duct, and upstream duct with test microorganism injection port, a UVGI (Ultraviolet Germicidal Irradiation) device mounting duct, a downstream duct with sampling port an off-glass pipe with HEPA filter.

In order to perform a complete test, UV-C Light Ultraviolet BioKit allows the measurements and control of air flow rates, air temperature, humidity and dilution concentration.

Test microorganisms have to be used for the test, like Serratia marcescens, Bacillus subtilis, Cladosporium Sphaerospermum Safety consideration about UV-C light and biological safety:

Bioaerosol Sampling System

Bioaerosol is a component of Particulate Matter (PM) in the atmosphere, and consists of airborne particles that have a biological origin.

Bioaerosol is a mix of:

Airborne microorganisms including some pathogens in indoor air may cause different types of diseases or adverse health effects on humans. Among different air disinfection techniques, ultraviolet germicidal irradiation (UVGI) has been used for several decades to effectively inactivate the airborne microorganisms in indoor air and hereby prevent the transmission of a variety of airborne infections.

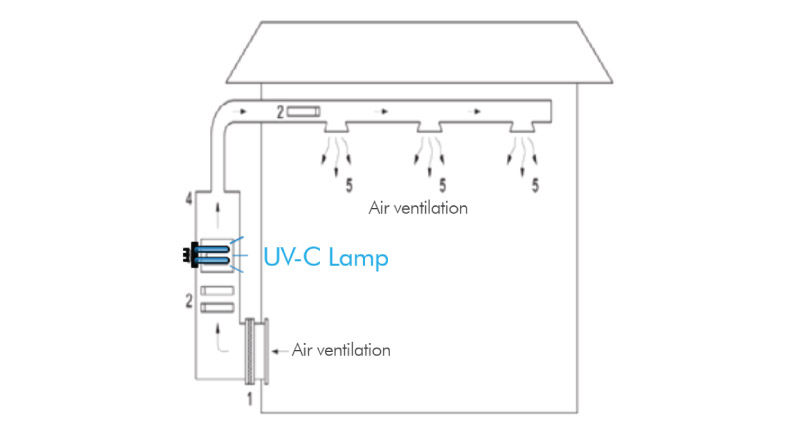

The International Standard ISO 15714 describes the test methods to evaluate the UV doses to airborne microorganisms transiting in-duct ultraviolet germicidal irradiation devices. In duct UVGI devices are a primary form of air disinfection method by UV lamps mounted in heating, ventilation and air-conditioning (HVAC) systems to irradiate the microorganisms in air with high intensities.

Scheme

Diagram of an in-duct UVGI device in an HVAC system

Applications

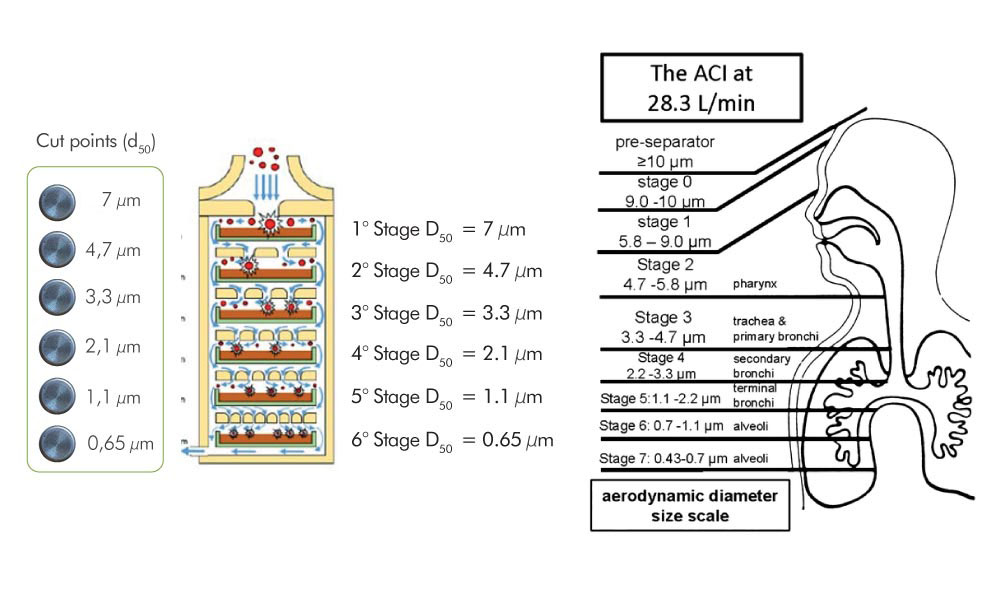

6 Stage Andersen Cascade Impactor

Principle of Operation

From the standpoint of respiratory deposition, the human respiratory system acts as an aerodynamic airborne particle classifier.

The multi stage impactor, based on the particle inertial impaction principle, simulates the human respiratory tract (extra thoracic, tracheobronchial, alveolar).

The micro holes in each of the 6 impactor stages act as nozzles that, in function of the hole diameter and impaction distance, lets the caption of a dimensional range of particles, with a defined cutoff diameter and a characteristic efficiency impaction curve.

The special design of the multi stage impactor assures the collection of size-segregated particles that are suspended in the sample air.

UV-C Light Ultraviolet Sampling System

Features

In accordance with:

ISO 15714 : 2019

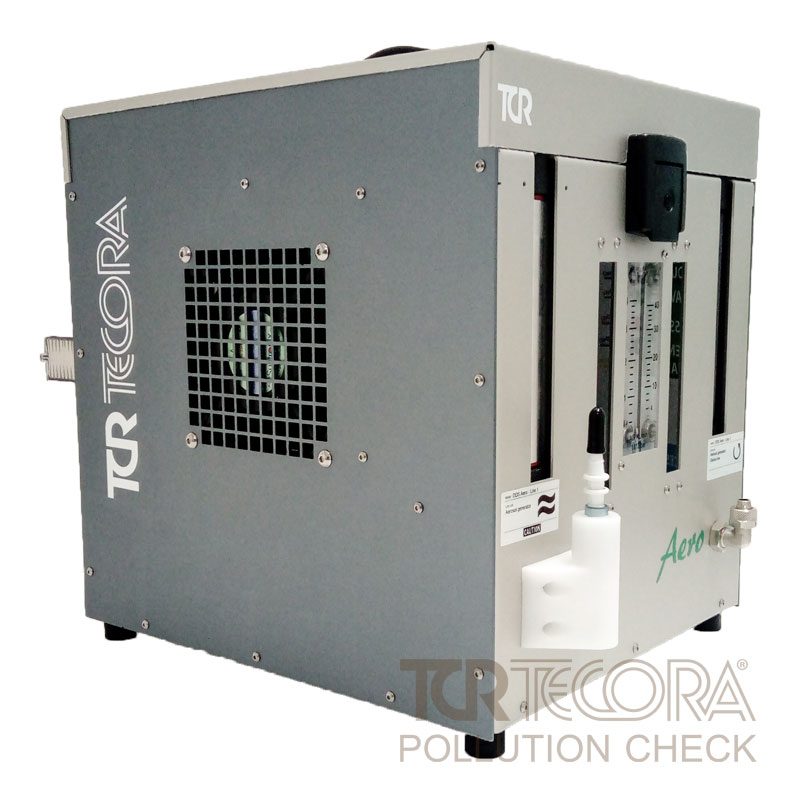

Particle Nebulyzer

COD: AC99-120-0000SP

- Aerosol generator compatible with all type of liquids, suspensions and solutions;

- Integrated pump (no compressed air required);

- Adjustable Nebulyzing and dilution air (dry) flow;

6 Stage Andersen Cascade Impactor

COD: AC99-120-0002SP

- Functioning principle: Inertial impaction;

- Required Flow: 28,3 l/min (1 CFM);

- Direct sampling on 90 mm petri plates;

- Made of corrosion resistant material

Irradiation Aerosol Chamber (in-duct UVGI)

COD. AC99-120-0009SP

- Galvanized steel or aluminium;

- Sampling port (Andersen impactor inlet);

- Microorganism injection port (aerosol generator inlet);

- Ventilation fan grid.

Electronic Flow Control Sampler

COD: AA99-000-0030SP [Bravo Basic H]

COD: AA99-000-0740SP [Bravo X BIO] (differential pressure)

- Automatic flow regulation;

- Flow range: 0.5 to 70 l/min;

- Available models: Basic H or X-BIO;

- HEPA filter (pump exhaust) included.

Download the Datasheet

For Further Information, Write Us!

For other queries:

Call Us

+39 02 3664.8635