G8

Isokinetic Automatic Sampling System

Main socket with FUSES

Pitot tube quick connectors

TC Connector Stack Fumes

TC Connector Impinger bath*

TC Connector Last Impinger*

TC Connector Heated Probe*

TC Connector Heated Box*

Heated device supply*

Inlet Gas with Protection Filter

BY PASS Regulation

Coloured Touch Screen

* Se presente tra le opzioni.

G8, 5th-generation Isokinetic Sampler

Compliant with:

EN 13284

EN ISO 16911-1

US EPA M5, M17

ISO 12141:2002

After more than 40 years of experience about automatic isokinetic sampling systems, after ISOSTACK B6(80’s-90’s) after the acclaimed ISOKINETIC G4 (2000-2020), the 3rd generation of isokinetic sampler is finally arrived. We are proud to introduce ISOKINETIC G8, the most advanced sampler in the market, updated to all EN and EPA standard as well as fully compliant to

the metrological chain requirements mentioned in the standard ISO17025.

The main components that has been the strength during these years has been readjusted to run with the new digital architecture. The last technology has been adopted to design the most as it is powerful electronic platform as it is simple. A pre-test period as confirmed the very high MTBF of all hardware and software. The very stable and easy to use G4 sw platform has been the base to develop the new G8 user interface.

The starting point and most important objective was: make the life of testing and sampling engineers simple.

Nowadays, during sampling activities, the mandatory rationalization of the working day impose to manage more sampling at the same time. The automation level of ISOKINETIC G8 makes that you don’t need to be worried about it.

Warning and alarm messages are sent to your phone via G8 app, so you have total control any time, anywhere!

Reduced Weight and Dimensions

The introduction of new internal components has led to a significant decrease of weight facing the request form the national requirements about human working load limits. The limited operating space in most of the sampling platforms has been the starting point from which our R&D has been engaged in order to design a sampler with better performances and better handling/transportability.

New Characteristics

Main Characteristics

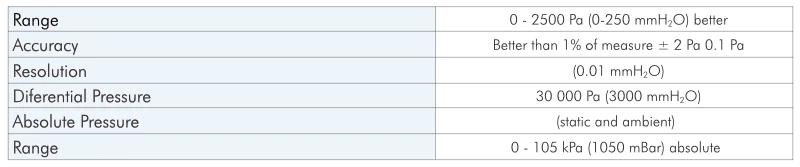

Technical Characterisctics

Temperature

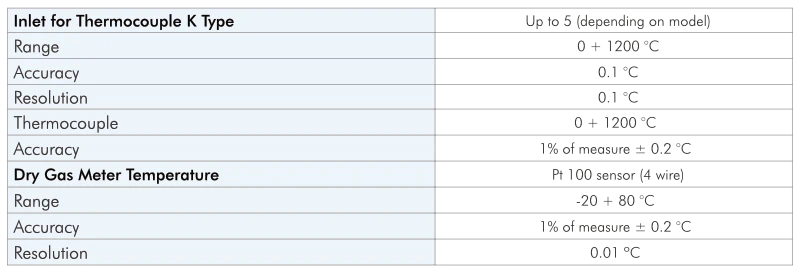

Volume measurement

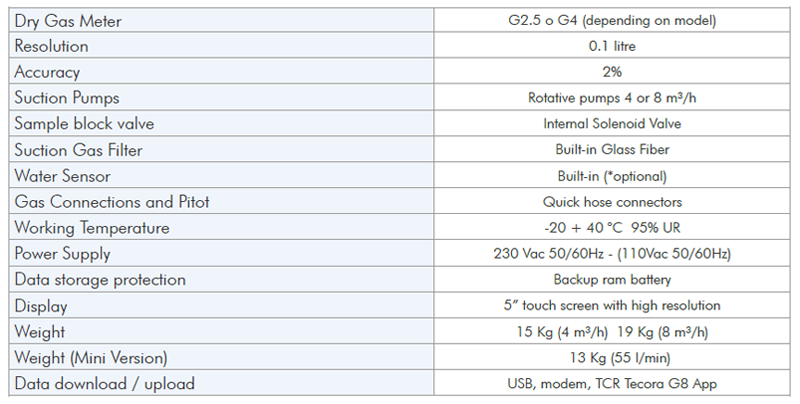

Codes

Download the Data Sheet of the New G8 Isokinetic

Do you need further information about? Write to us!

Call us!

+39 02 3664.8635