PFE Particle Filtration Efficiency

PFE Particle Filtration Efficiency

Because of the COVID-19 pandemic, the use of face masks became an essential tool in order to reduce the diffusion of the SARS-CoV-2 virus. In addition to surgical masks, dust masks can be used. These dust masks are classified as FFP1, FFP2 and FFP3 according to the regulation UNI EN 149, depending on their efficiency in filtering dust.

First categorisations and first uses of these masks have to be conferred to the world of individual protection on works involving the presence in the air of particles, produced by industrial production processes, and inhalable by workers. Some of which, if inhaled, could be dangerous for human health.

Particle dimensions and their effect on health

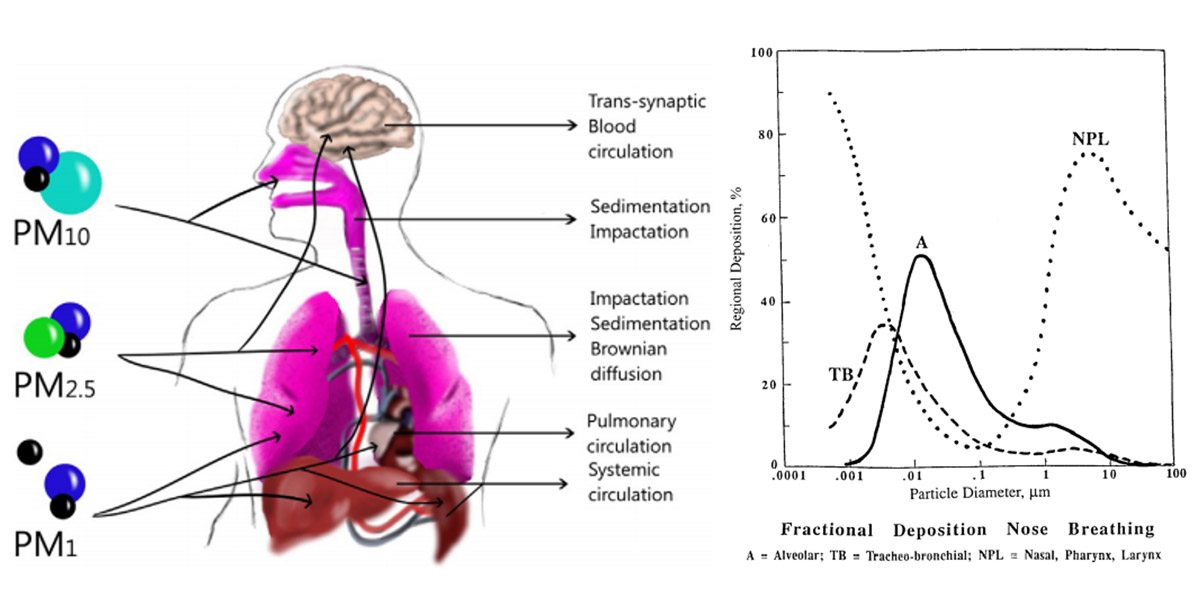

To better understand the potential risk of inhaling atmospheric particulate matter, it very is important to know how the size of the particulate itself, because it is a fundamental characteristic for determining its dangerousness.

Atmospheric particulate matter [1] [2] could be divided into 3 main categories: inhalable, thoracic and respirable, in the way they are defined in the regulation UNI EN 481.

To the first two classes, the inhalable and the thoracic, belong to those particles with diameters respectively greater than 10 µm and 2.5 µm. these particles are able to enter inside the respiratory tract from nostrils and mouth to the tracheal and bronchial tract, as shown in the illustrations underlying [3].

The third class of particles includes those particles with a diameter < 2.5 µm, that are able to penetrate to the alveolar level. At this stage particles with a diameter < 100 nm manage to go through the alveolar barrier and enter the circulatory system [4]. This last characteristic makes these particles more dangerous, because in this way they can reach and damage other organs.

Particles dimensions and dynamics through the respiratory tract and other organs. [3], [4].

Dust masks’ FFP (Filtering Face Piece) description and classification

Regarding the filtration capacity dust masks are classified in 3 categories, depending on the percentage of airborne dust that are able to stop. According to the regulation these protection devices have to be able to protect the user, and so filter, both liquid and solid aerosols.

The classification consist of three different types:

- FFP1: dust masks which have to guarantee a maximum test aerosols’ penetration ≤ 20%;

- FFP2: dust masks which have to guarantee a maximum test aerosols’ penetration ≤ 6%;

- FFP3: dust masks which have to guarantee a maximum test aerosols’ penetration ≤1%.

TCR TECORA® is interested in the development of an instrumentation able to test and verify that dust masks respect the filtration standards expected from the regulation UNI EN 149. Then with this instrumentation it is possible to reproduce the method test described in the regulation EN 13274-7, in order to have a check of the filtering efficiency if the test aerosol.

The experimental procedure consist of producing an aerosol which has to be used as a test aerosol to verify the filtration efficiency of the dust masks. Once the test aerosol is produced, with an optical particle counter it is possible to check the aerosol concentration in the measurement chamber, to check that this concentration is the same demanded in the regulation.

After checking the aerosol concentration into the chamber, the dust mask is inserted in order to intercept the air flow, set up with the same floe rate requested from the regulation, without any leak. Finally, a second measurement of aerosol concentration is carried out in the chamber downstream of the mask and by comparing the concentrations measured in the two different moments (with and without the mask) it will be possible to carry out a classification of the filtering mask according to the penetration efficiency, evaluated by a comparison of the concentration measurements before and after filtration by the filter mask.

BIBLIOGRAPHY

[1] Xavier Querol et al. ‘PM10 and PM2.5 source apportionment in the Barcelona Metropolitan area, Catalonia, Spain’, Atmospheric Environment, Volume 35, Issue 36, December 2001, Pages 6407-6419, https://doi.org/10.1016/S1352-2310(01)00361-2

[2] XEarPro Srl, Post: ‘Aerosol, inquinante atmosferico’, https://xearpro.it/aerosol-inquinante-atmosferico/

[3] Carlos I. Falcon-Rodriguez et al. ‘Aeroparticles, Composition, and Lung Diseases’, Front. Immunol., 20 January 2016, https://doi.org/10.3389/fimmu.2016.00003

[4] Oberdörster, G. Pulmonary effects of inhaled ultrafine particles. Int Arch Occup Environ Health 74, 1–8 (2000). https://doi.org/10.1007/s004200000185

TCR Tecora

TCR Tecora

TCR Tecora

TCR Tecora TCR Tecora

TCR Tecora

TCR Tecora

TCR Tecora TCR Tecora

TCR Tecora