Dryx

Gas Conditioning System

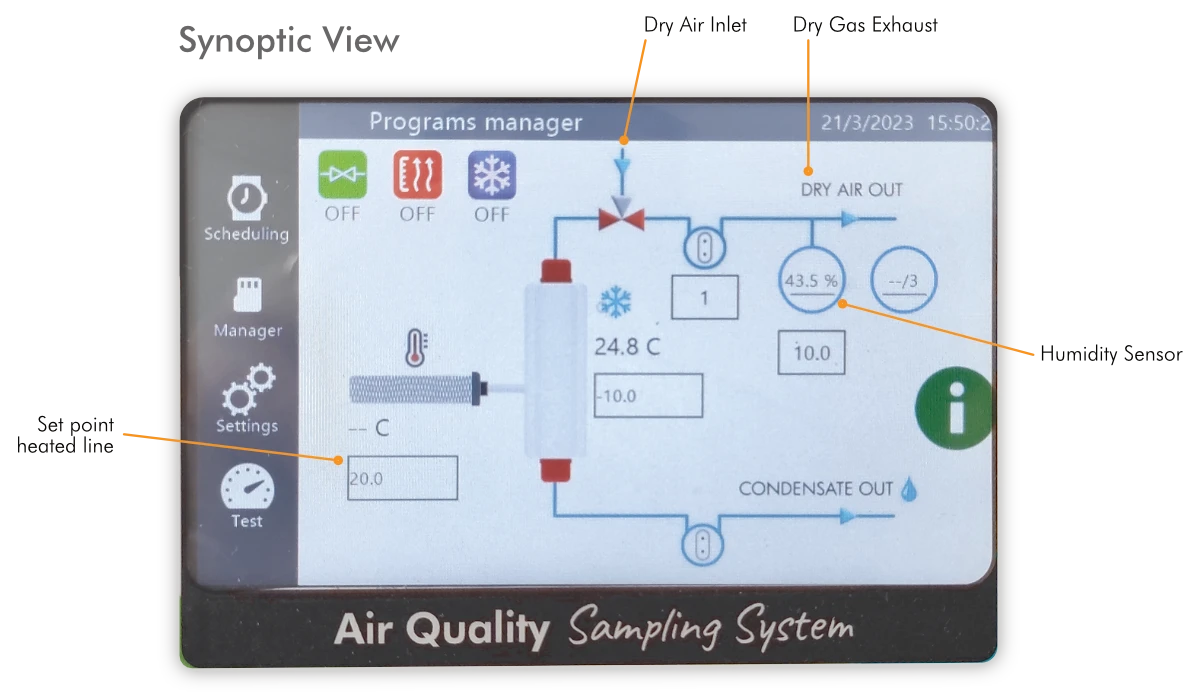

Color Touch Display

Transport Handle

USB Connector

Heated Line Connection

Gas Inlet

Adapter for Heated one

Heated Probe Connection

Liquid Pump

Double line for Dry gas Exhaust

Power Switch

Cooling Controller

Holding Handle

Fan

Heated Line Controller

Ethernet Connection

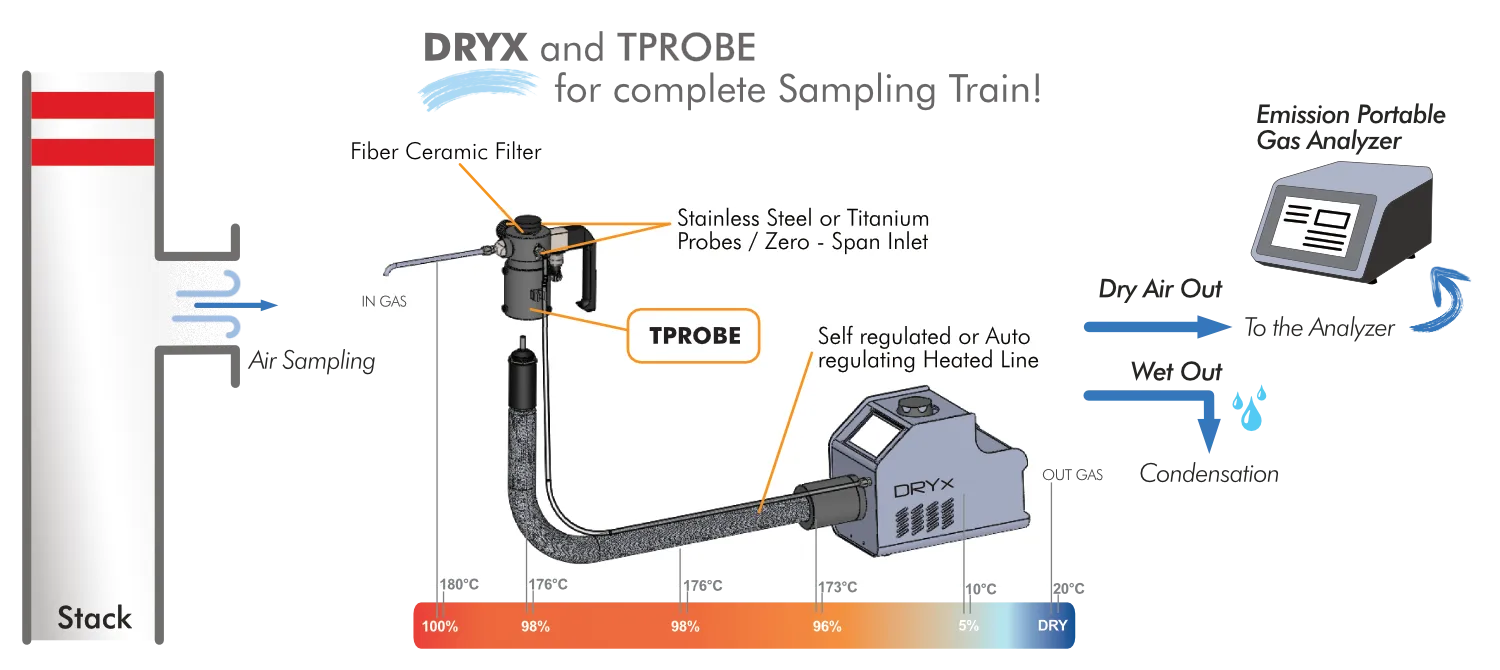

DRYX Gas Conditioning System

Compliant with:

UNI EN 14385, CEN/TS 13649, UNI EN 12919, UNI EN 13284, UNI EN 1911, UNI EN 13211, UNI N 14790, ISO 9096, UNI EN16911.

DRYX is a new TCR TECORA® concept device for gas sampling and conditioning. Differently from the other systems, DRYX is a real “sampling management platform”, complete with all devices needed to perform any activity related to extract a gas from a duct, without altering the chemical and physical characteristics of it.

DIGITAL MANAGEMENT

The color touch screen display, fully field tested in all samplers produced by TCR TECORA® has been used also for DRYX. User friendly menu allows the operator to switch on the cooler in few seconds. The electronic microprocessor manages the start-up phase, waiting for stabilization of all parameters and, when it’s ready, it starts to sample.

ONE “BOX” FOR ALL

DRYX has a membrane pump built in PTFE to suck the gas from the duct, reducing the stress of the analyzer pump. An adjustable bypass allows to regulate the optimal flow to the analyzer without over/under pressure that could damage it or alther the analyzer data. An optional flow measurement sensor permits to monitor the exact quantity of gas required from the analyzer.

ONE “BOX” FOR ALL

DRYX has a membrane pump built in PTFE to suck the gas from the duct, reducing the stress of the analyzer pump. An adjustable bypass allows to regulate the optimal flow to the analyzer without over/under pressure that could damage it or alther the analyzer data. An optional flow measurement sensor permits to monitor the exact quantity of gas required from the analyzer.

LINE AND PROBE TEMPERATURE CONTROL

Two built-in stand alone temperature controllers manage the heating of the sampling probe inserted in the duct and the PTFE/Stainless steel heated line. The controllers are connected to the microprocessor via RS 485 bus.

This enable to set the set point directly from the user interface.

HUMIDITY CHECK

Before the gas output, an analog humidity sensor monitors the quantity of H2O mixed in the sample. This is very important to preserve the analyzer from possible moisture that could accidentally enter in the internal circuit causing important and costly damages. An automatic routine checks the level of condensation and, in case of high level, activates a 3 way solenoid valve that opens a way to atmospheric vent. The sample is stopped and the analyzer is safe!

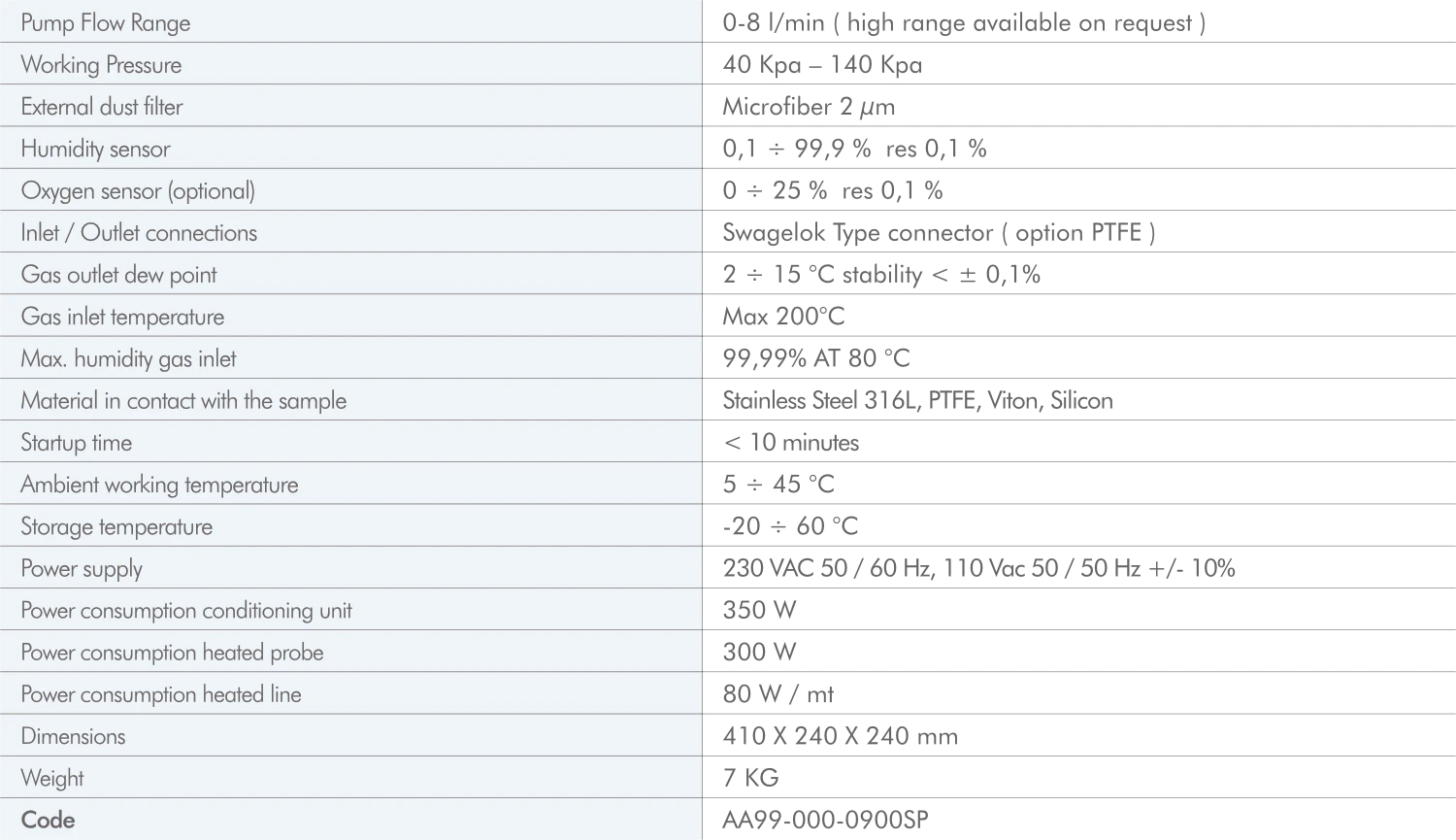

Main Characteristics

Technical Characteristics

Download now the DRYX Brochure

Do you need further information about? Write to us!

Call us

+39 02 3664.8635