Echo TUBE

Sequential Sampler for

Gaseous Compounds

Adsorbent vials compartment

Stand

Gas Sampling Head

Sampling Line

Volumetric meter

Laminar Cell (Flow measurement from 10 cc/min)

Ultrasonic Anemometer

Echo Tube Sequential Sampler for Gaseous Compounds

The ECHO TUBE Sequential Sampler for Gaseous Compounds has been studied and designed for sequential sampling on vials for gaseous compounds at flowrate from 100 to 200 cc/min, and to comply to regulation request on sampling field, prescribed in the EN 14662-2:2005 “Ambient air quality – Standard method for measurement of benzene concentrations – Part 2: Pumped sampling followed by solvent desorption and gas chromatography”

In compliance with:

Formaldehyde

ECHO TUBE with additional options, meets all the indications of the norms EN ISO 16000-3 and EPA TO 11-A about indoor and outdoor formaldehyde sampling.

Temperature regulation system and post-sampling maintaining (option). The regulations require, in order not to alter the sample and affect the analytical result,

to heat the vial if temperature drop below 10°C. Also, sampling completed, the vials have to be cooled at 4°C.

This procedure is particularly suitable in case of 3-hour sampling within 24-hour day.

Line ventilation before and after sampling (option). Before starting the sampling, an automatic system allows ventilation and conditioning of the incoming supply air line. At the next sampling, the operation is repeated.

Heated line (option). The external sampling tube is made of AISI 316L stainless steal and heated to max 50°C (option) as required by standard. This is particularly suitable for low temperature, even below 0°C.

Scrubber to eliminate ozone (option). Particular attention has been paid during the design phase to allow the user to use both potassium iodide filled vials available in the market and as well as system with copper coil to be treated with potassium iodide (procedure described in the standard).

Up to 32 Vials!

The containment structure and an additional vials support system (option) allow sampling up to max 32 vials, commonly available on the market. The vials manifold supports are equipped with stainless steel electro valves on both sides to seal the vial before and after sampling, avoiding external contamination.

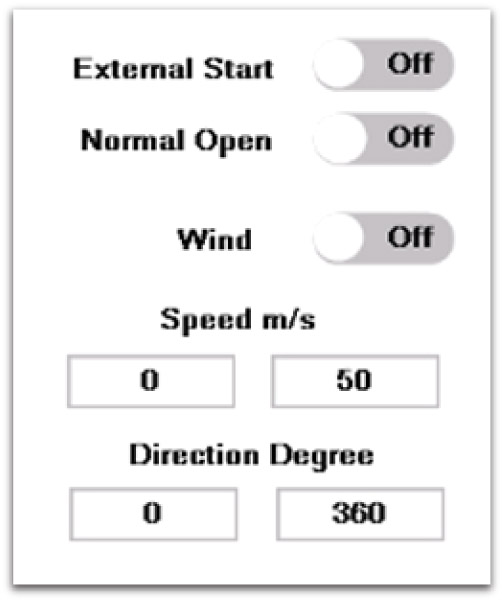

“EVENT BASED” Selective Sampling

Via digital input (from data logger or other device) it is possible to command a sampling sequence. Furthermore, with a wind speed/ direction sensor (optional) and dedicated programming, the sampling is activated with predetermined flowrate and timing.

Main Features

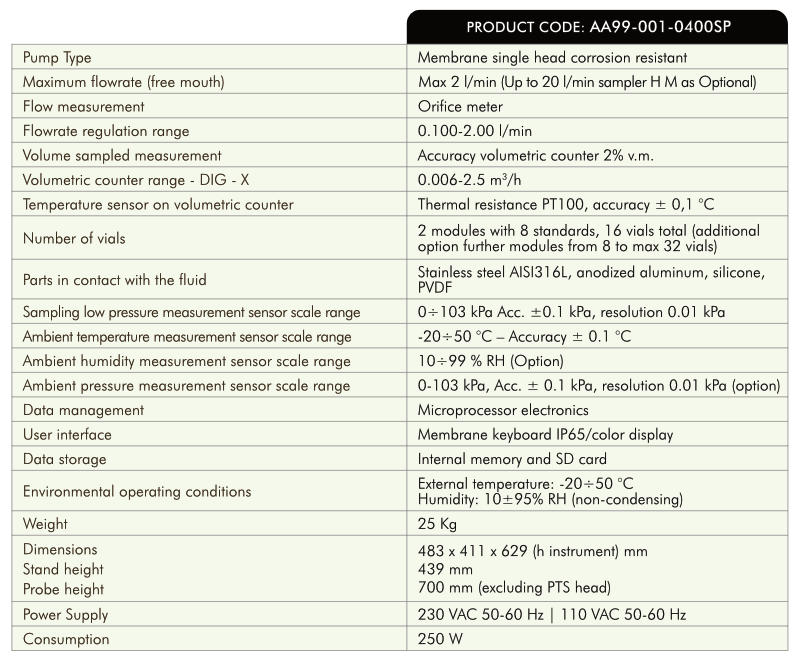

Technical Features

Download now the ECHO TUBE Brochure

Do you need further information about? Write to us!

Call us

+39 02 3664.8635